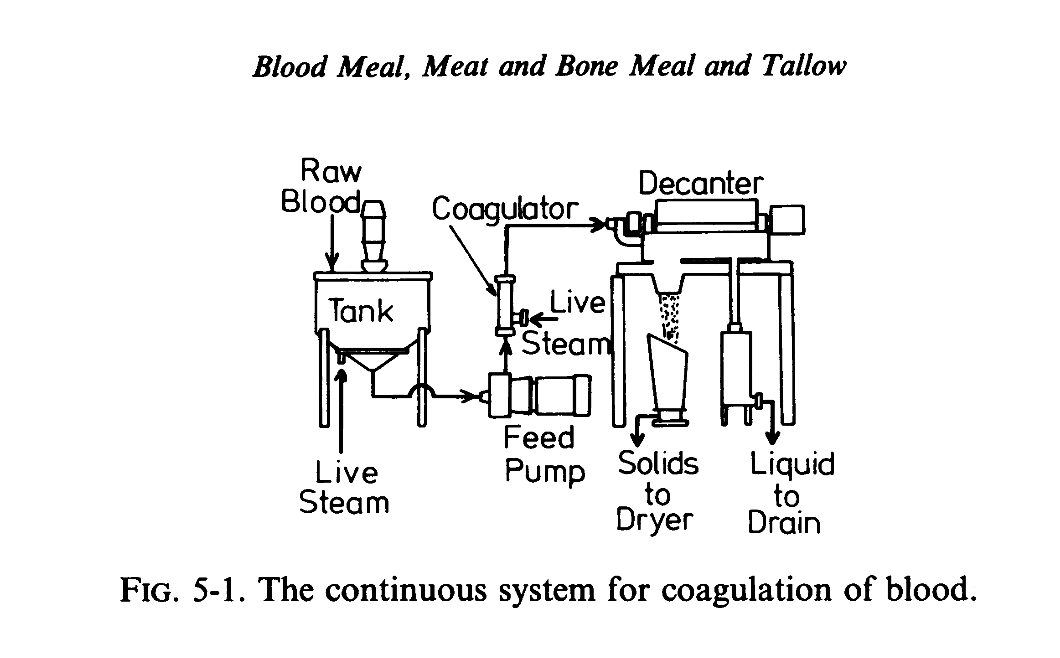

تخثير الدم

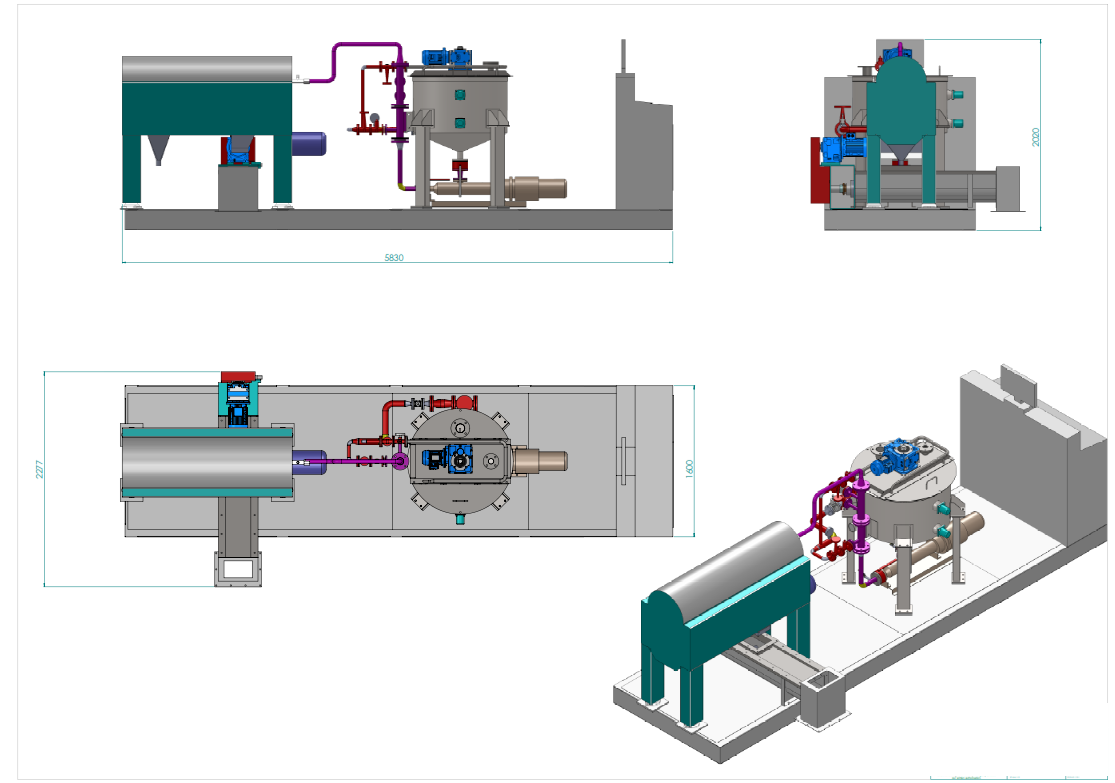

- The idea is based on storing the blood in a receiver equipped with a mechanical stirrer that works on continuous mixing, and direct steam is pumped through it with a steam line coming from the boiler, and this receiver is called a pre-heater tank

- The blood is then withdrawn from the pre-heater tank by a single screw pump, and then pumped through the main coagulator pipe, which is a line of stainless steel pipes equipped with direct steam valves that pump steam through the flow of blood liquid in this complex … This results in red blood cells coagulation and clumping within the plasma and water liquid, and the mixture is ready to separate the water from the coagulated blood in preparation for drying and obtaining the blood powder

Pumping is completed through the coagulation complex and up to its exit to the mechanical separation of water from the mixture, which is carried out in two ways:

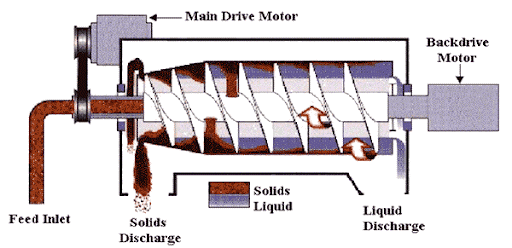

1-Using the decanter centrifugal separation device, which works to separate the water from the clotted blood with a difference of densities and increase the centrifugal force G-force to a large value, resulting in the deposition of blood particles on the walls of the decanter and sweeping them with the internal screw on one side and extracting the water on the other hand

2-The use of special mechanical sieves of high frequency capacity and membranes with narrow permeability that work to draw water without clotting blood, and thus the separation is done

- Mechanical separation extracts 75% of the water from the coagulated blood mixture, leaving a foamy which the proportion of water to the coagulated blood is 50%, and we move the new product to the drying stage in the disc dryer

- Disc dryer reaches 25% of the coagulated blood mass mixed with water (about 250 kg per ton of blood) and works to evaporate the water from this mixture and only the coagulated blood remains after drying, which turns into powder during drying.

- The dryer is provided with a cyclone to prevent particles from coming out with the fumes emitted with drying, which (vapors) exit from it to the condensers and odor prevention systems to get rid of them permanently.