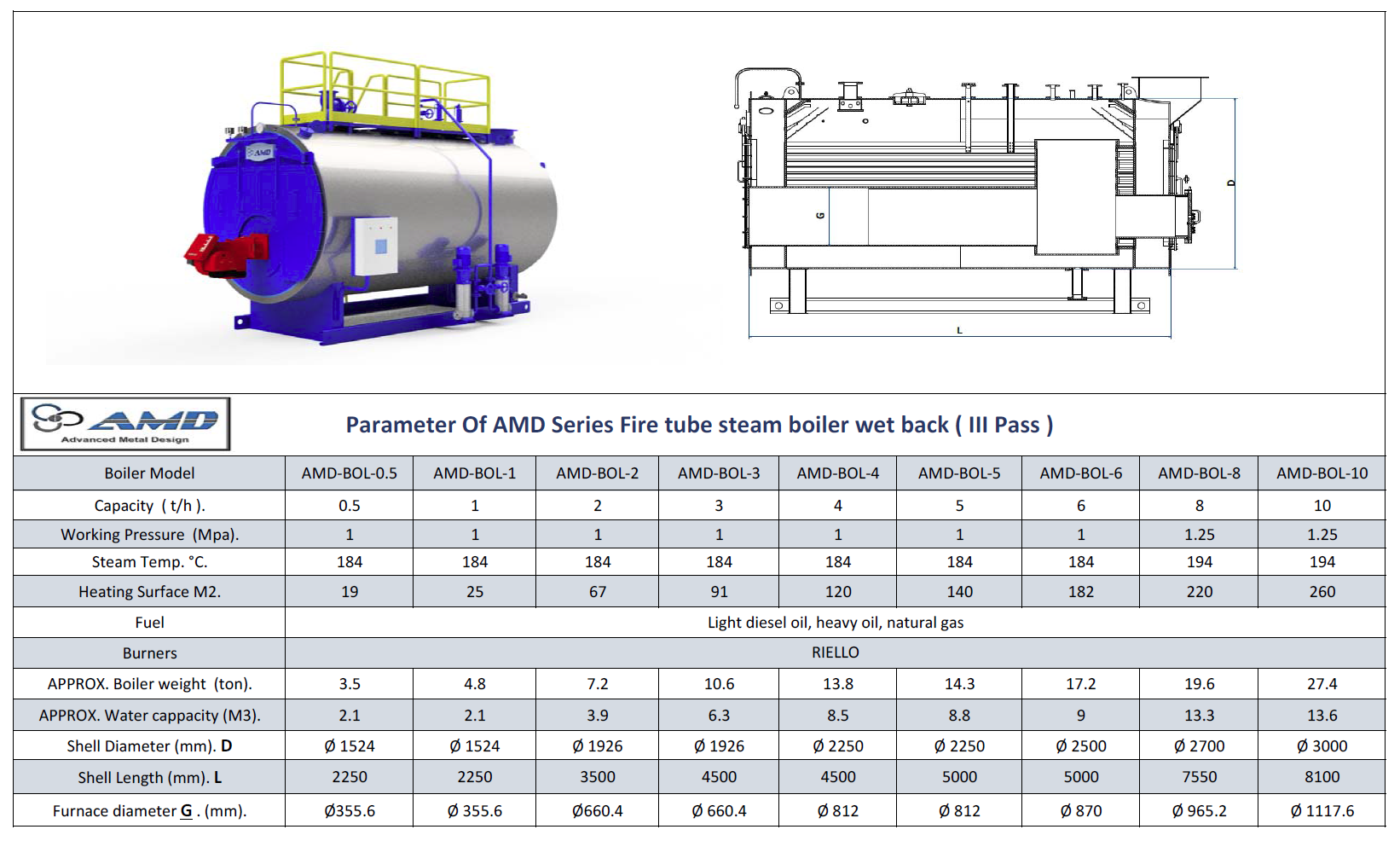

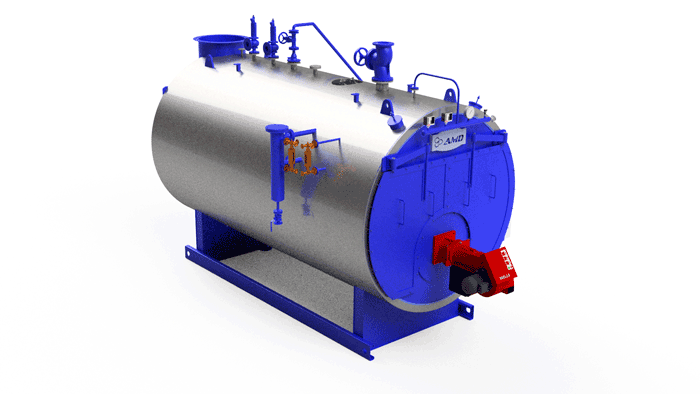

الغلاية

- AMD produces steam/hot water boilers with capacities from ¼ ton to 20 ton with operating pressures of up to 20 bar, according to the customer’s request.

- We design the boiler with three flame paths. This design provides maximum heat transfer, maximum steam storage, and ease of maintenance.

The boiler is Wet Back type, which achieves:

1- Long life of the boiler

2- Complete safety in operation

3- low fuel consumption

4- The absence of refractory brick buildings such as the dry back type.

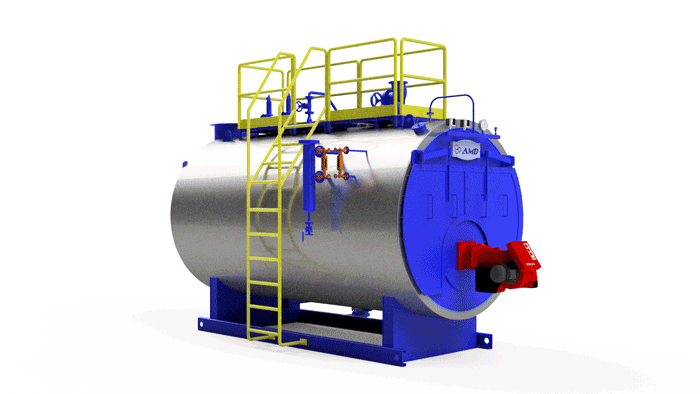

the design is made according to international specifications and ASME Code, and all our designs are approved by Cairo University, the approved authorities and the Standards and Quality Authority, in order to facilitate the boiler licensing process.

-

All stages of boiler manufacturing are inspected to ensure their compliance with international specifications and under the supervision of Cairo University on all steps of welding and assembly, including:

1- Chemical and mechanical analysis of raw materials

2- Crack detection tests using magnetic waves and color solutions

3- Final test of the product by hydraulic press

- The entire boiler body and the flame house are made of boiler iron A516-GR70

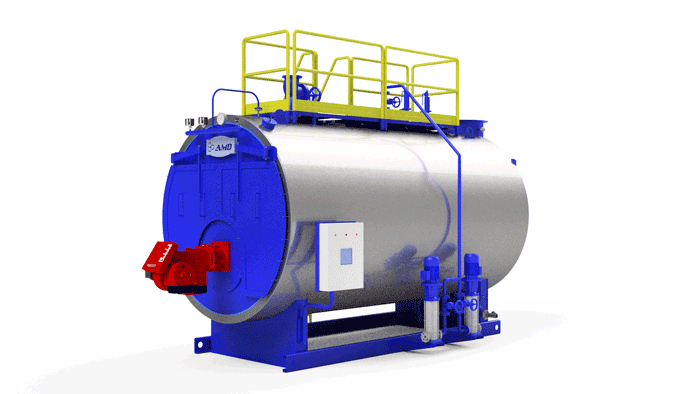

- All pipes used in Ukrainian boilers

-

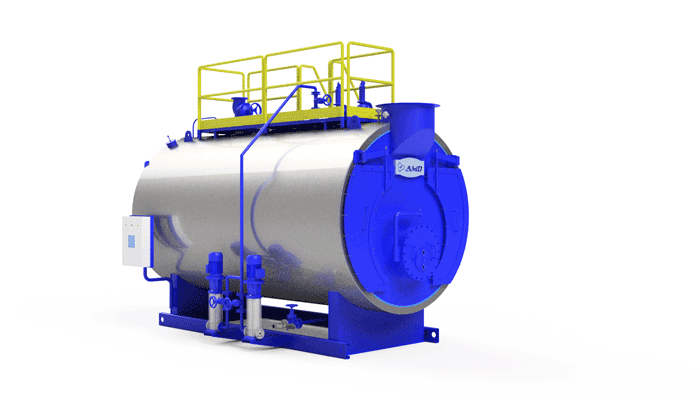

Boiler control panel:

utilizing latest technologies to control boiler pressure and steam temperature, operate the burner, replace pumps, and blow up the boiler with various alerts for any sudden rise in pressure or increase in the temperature of the flue gases or other important readings.

Through a PLC control unit, industrial touch screens, and an easy-to-use and adjustable operating and protection program, according to the customer’s desires.

This is one of the highest safety systems in controlling the boiler and showing malfunctions and alerting them through the appearance of fault written on the panel and is equipped with an alarm siren to alert.

all components of the European-made panel

Boiler accessories:

1- Italian-made burner or according to the customer’s request

2- Two (2) Italian water level indicator devices

3- Two (2) Italian water feeding pumps

4- Two (2) safety valves to open in case of pressure increase

5- Two (2) pressure stat to control the maximum pressure of the boiler

6- One (1) manual sprayer that is connected to the PLC panel

7- One (1) manometer pressure gauge

8- Number (1) automatic blow valve that works with air

9 – Two (2) Italian-made electrode groups

10- One (1) valve to control the ejection of steam

11- Number (1) vent valve