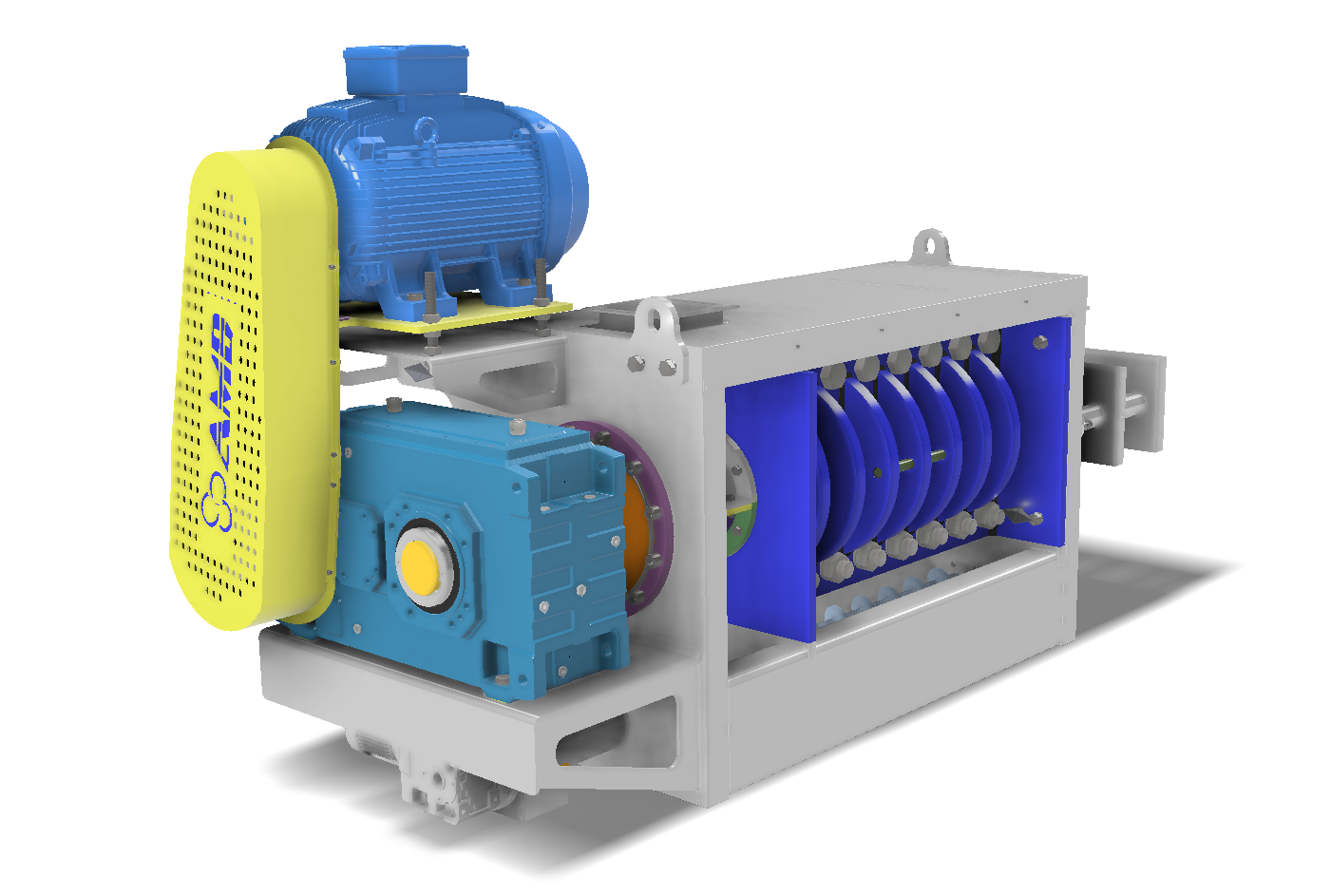

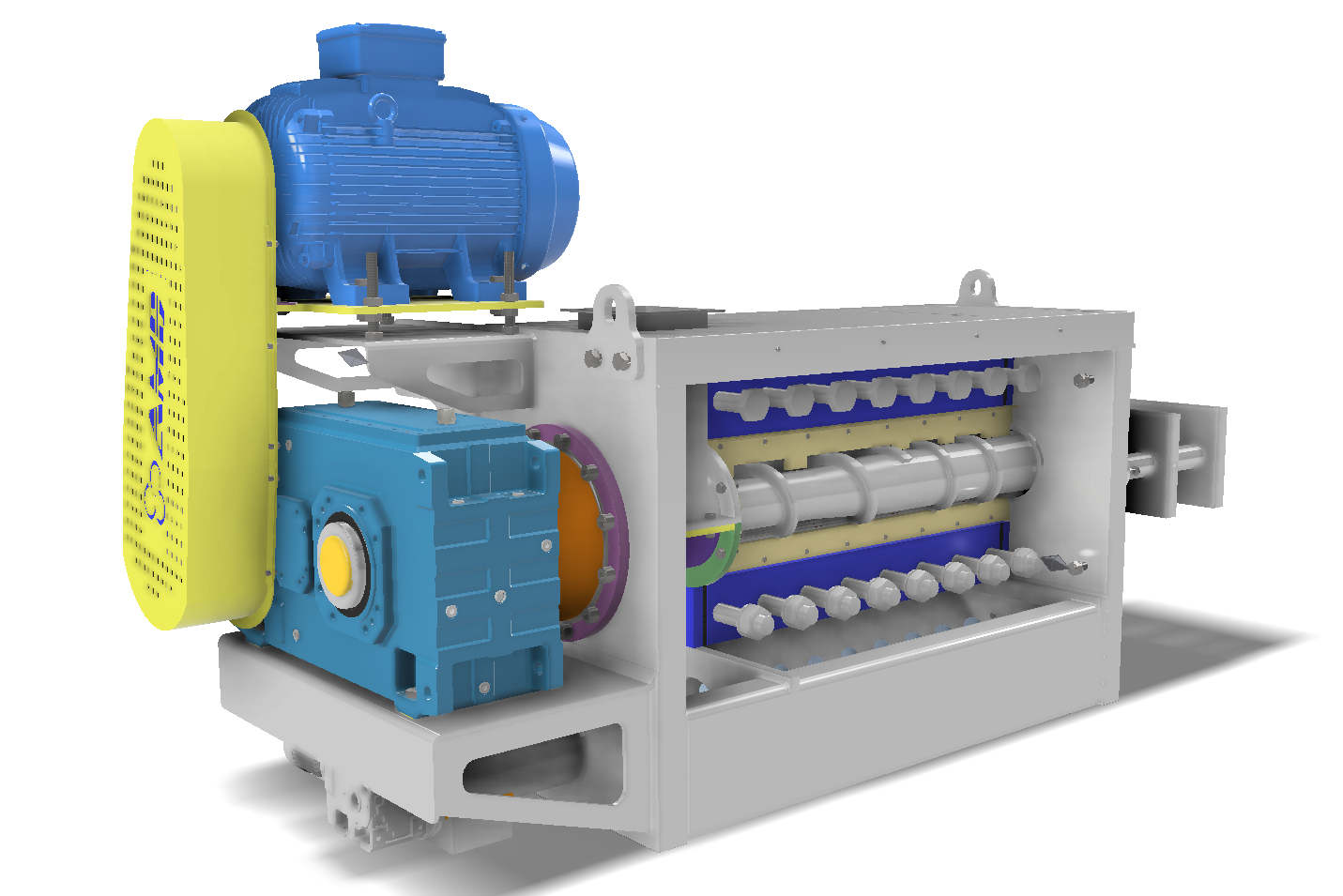

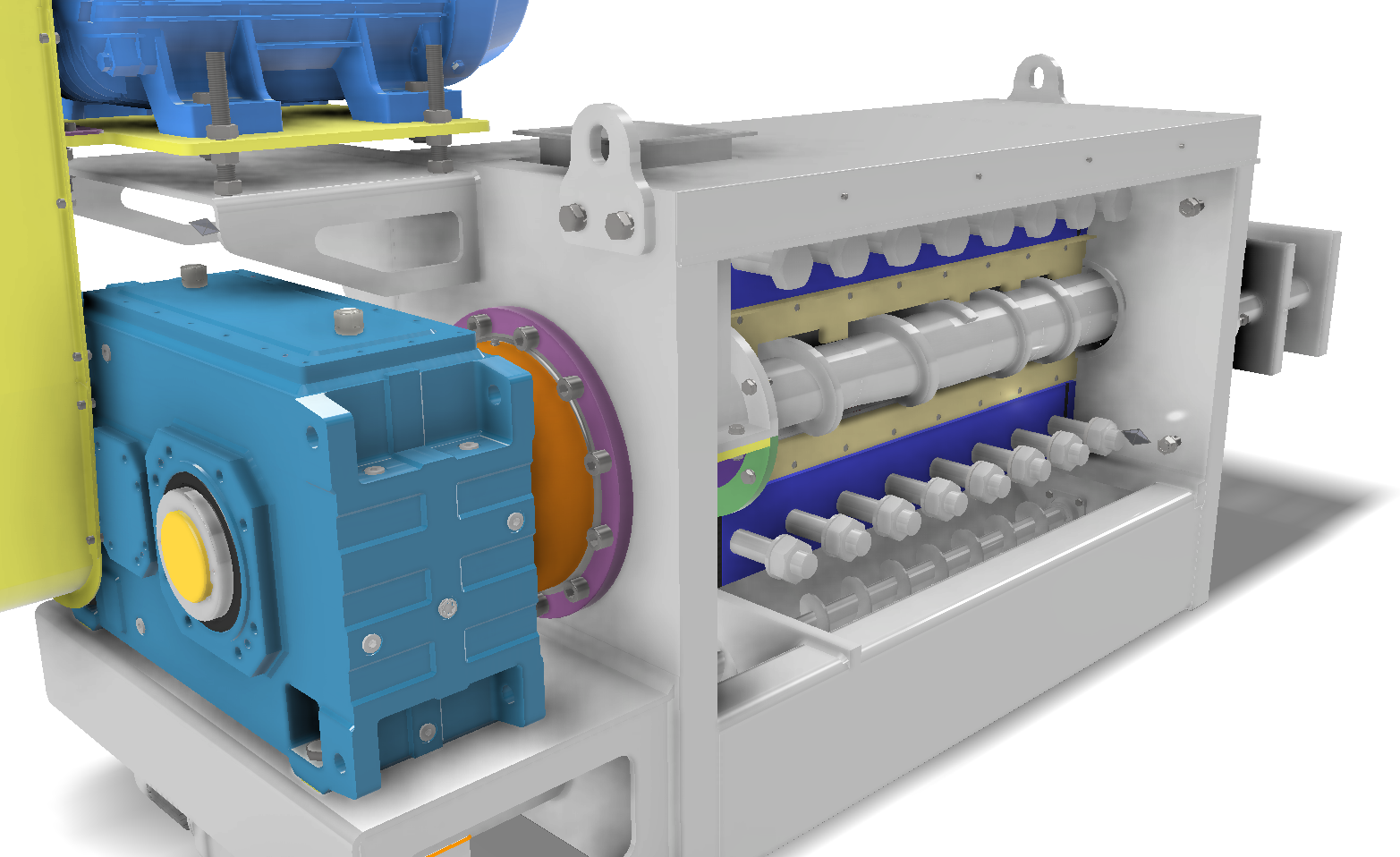

Fat Press Screw

- It works to extract the fat content of the by-products of cooked and dried animals and poultry, in a continuous flow. This allows you to get a finished product with a low-fat content.

- When the product passes along the spiral shaft, the fat is pressed out through the bars surrounded by the cage, and the product is compressed. The fat flows into the collector sump, where it is transferred through the auger to the outlet and through it to a tank to store the fat and the oil that has been removed from the operation.

The press is used for many industries, as it squeezes the oilseeds

- The amount of pressure on the product and squeezing is controlled by the hydraulic chock unit in the fat press.

- The temperature of the product entering the press must be high to easily extract the fats.

- 2000 kg / hour “there are different sizes according to the customer’s choice.”

- It works with a 75 hp engine and a high-quality heavy-duty gearbox.

- The pressing process leads to raising the percentage of protein, lightening the color of the product, increasing the smoothness of the product, and then raising the efficiency of the product and improving it, and this leads to raising the marketing value of the product.

- All materials are from 52 ultimate stress except for the stainless-steel side cover.