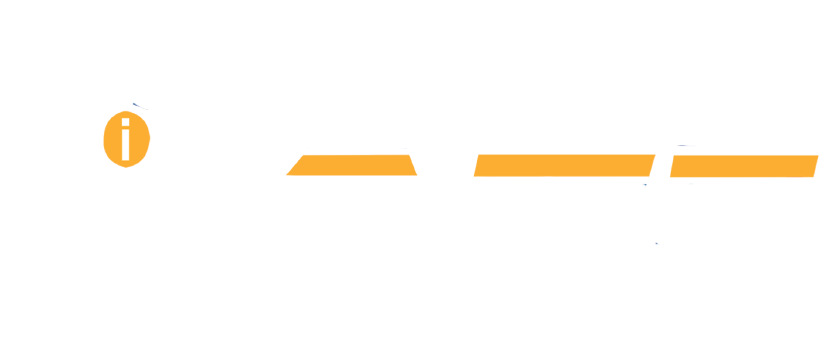

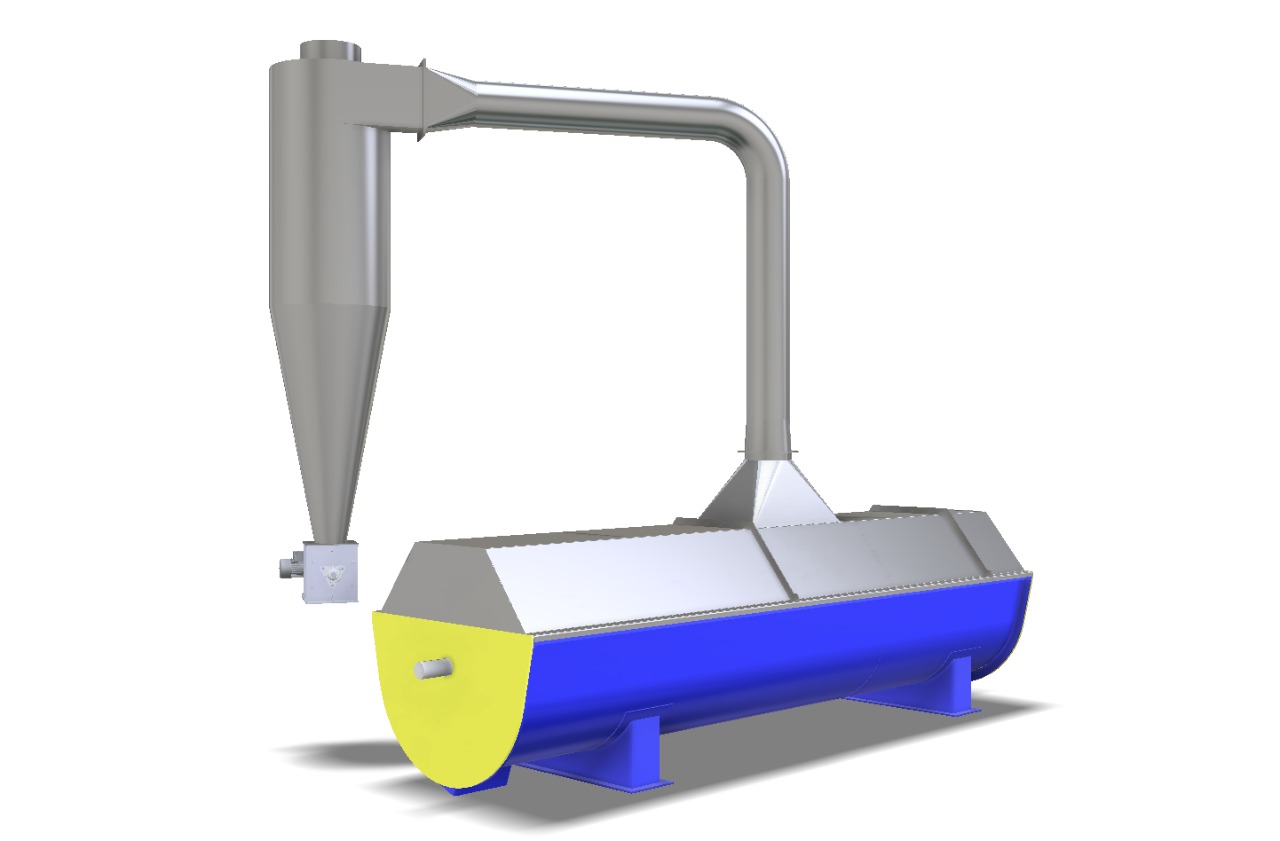

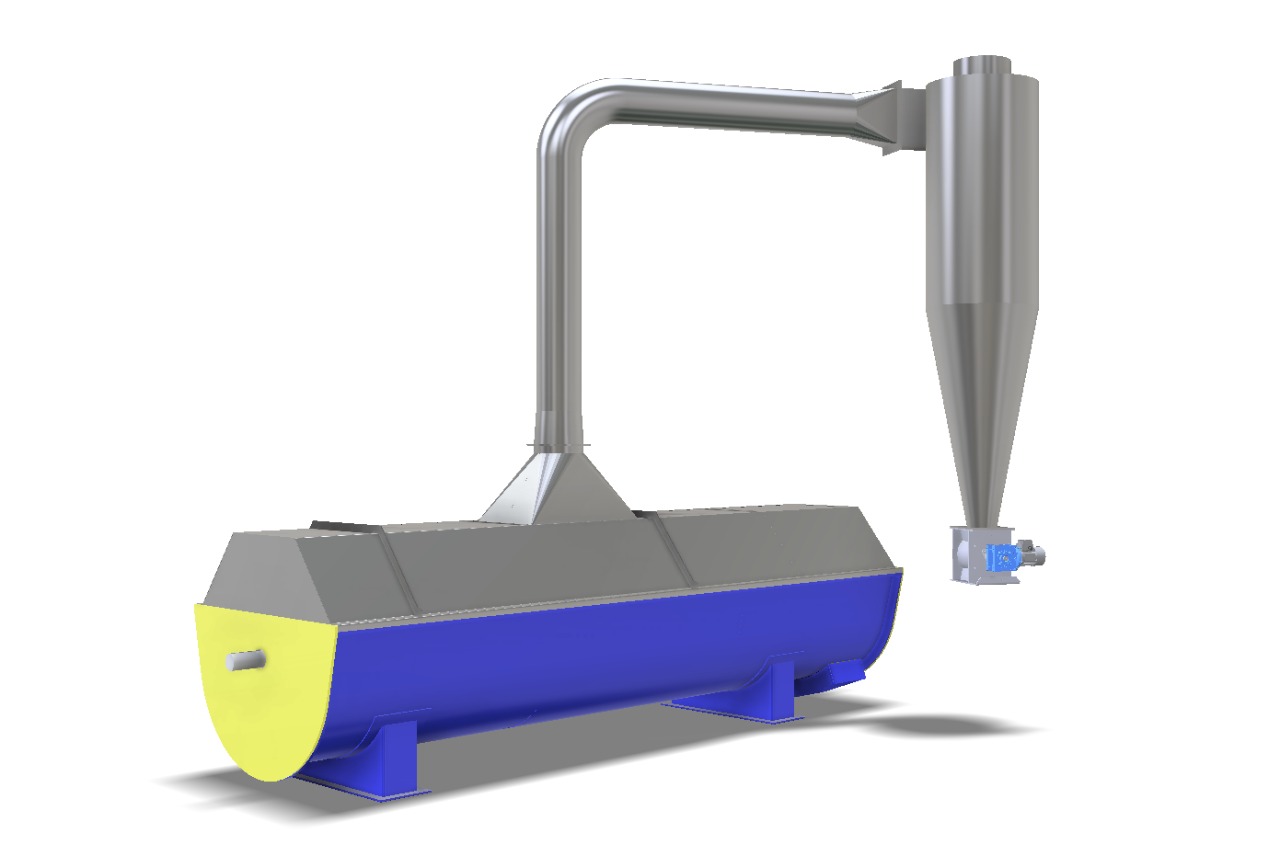

meal cooler

- Ambient air is used to cool a large batch of the final product (usually derived from poultry, fish or meat) after it has gone through the drying or cooking process. Cooling helps make the product more brittle, and therefore easier to grind.

- Most importantly, this cooling also enables to ensure that storage temperatures are kept below 50°C, to help prevent any risk of the meal spontaneously igniting. The cooler itself is essentially a long cylinder equipped with a flap.

- The stirrer moves the hot product (usually 90-110°C) through the coolant, while counterflow of cooling air is drawn through a centrifugal fan. The cooling air you use can be either ambient air or air from other suitable processes elsewhere in your plant – usually approx. 20-30°C above ambient temperatures.

- It is manufactured from iron thickness of 6 mm.

- The capacity of the cooler is 5 tons / hour.

The cooler include cyclone to trap the small particles and recycle it back.